Today I picked up the necessary ingredients from Fermentation Solutions for this years Zinfandel. Tomorrow is the 2014 harvest of the Vineyard Grapes and I am reviewing our protocols for this year. Hopeful this will serve to remind me what the process consists of in future harvests. I tend to forget.

Day One – Harvest

Check Brix on Grapes with Refractometer. We are aiming at 24-25 brix. Plan on picking grapes when it is cool. Stems should be turning brown, seeds also from green to brown and they should taste sweet. Just before raisining fruit is high in sugar and should be picked if the brix are low. At 25 we want to avoid them so we don’t have too much sugar in the must.

You may have to pick the grapes a bit earlier if the acid begins to plummet, or get yourself a nice bag of tartaric acid for adjustments — every winery should have a 50 lb. (23 kg) bag stashed away just in case.)

A. Sanitize all containers and equipment with solution of 3 tablespoons of Potassium Metabisulfite per gallon. Rinse and don’t re rinse with water.

B. Clean, Oil and sanitize clippers, wear gloves, and pick grapes and put in blue bins.

Don’t Cut what you cant see. Punish the Vine, pamper the cluster, Don’t yank on clusters. Don’t knock berries off. No Green or light colored (secondary clusters), Pick only those grapes that look good enough to eat. Don’t overfill baskets–dump when they get a bit full. Don’t push down on clusters in bin. Never put anything but grapes in bucket!

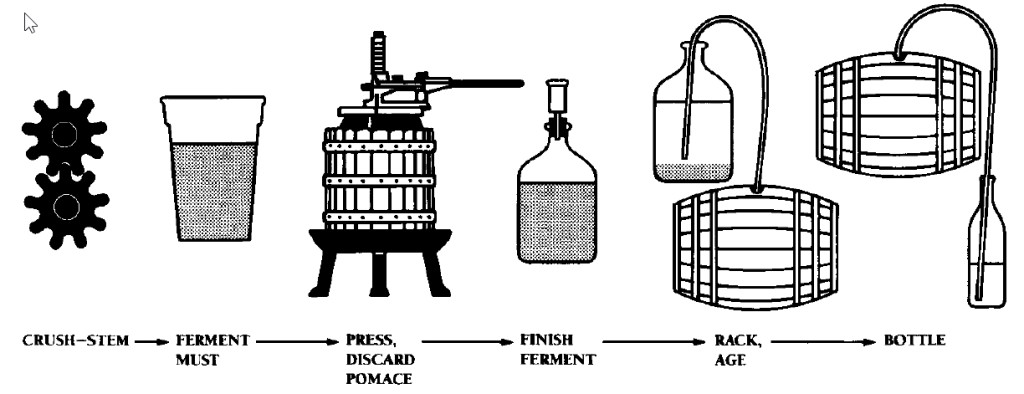

Once all grapes are on white tarp, get two stools and destem grapes into a small bins to transfer to Fermentation Container. The Zin is fermented on the skins and pressed after fermentation which extract the flavor and red color from the skins. Avoid too much green stem in must. Just pick them off the stem and don’t crush. This will result in a deeper color and flavor. Raisins are picked into must if original brix is low. If brix is 23 or 24, mix in raisins.

Once all the grapes are de stemmed into the fermentation container, we add Potassium Metabisulfite at 1 Teaspoon per 20 gallons and lightly crush and stir till fluid.

Let grapes sit a day to all meld together. Its unnecessary to crush grapes, the holes in the bottom of the grapes where stem was is all that is enough for yeast to penetrate skin and ferment grape.

DAY TWO – rehydrating yeast and adding to must

We chose LAVIN D254 which is used to ferment big full bodied red wine, Mediterranean Style Red Wines. Moderate fermentation speed. Temperature should be 55-78 degrees throughout fermentation process no big swings. Start it a bit warmer than 55, then move to cooler temps.

Four Steps for Rehydrating Yeast and Inoculating MUST

-Suspend 750 ML of 110 degree clean water with GO FERM (32 grams)

-Once temp of GO_FERM drops to 104 degrees, add entire packet (25g) of YEAST (ICV-D254) and stir to break up clumps. Let stand for 15-20 minutes and stir gently again.

-Slowly over 5 minutes, add 750 ml of MUST solution to YEAST solution. This acclimates the yeast to right temperature slowly so they don’t die. THIS HELPS YEAST ADJUST TO COOL TEMPERATURE OF MUST.

-Add Yeast Slurry to fermentation vessel and mix into MUST

Push grapes under must twice a day.

DAY THREE Malolactic Fermentation Culture and Fermaid K (1/2 pack)

Add Malolactic acid Vino Flora to MUST by first takeing some must and stirring into . This stuff needs to be in freezer before use. (Putting in the day after yeast is called ” Concurrent Malolactic Fermentation.”

Add Fermaid K one half the pack (13 grams)

From here on out, we must keep the must somewhere between 55 and 78 degress and as constant as possible.

We must push the top grapes under twice a day. Measuring BRIX with HYDROMETER daily to monitor the fermentation

process.

AS FERMENTATION PROGRESSES

When we reach around 17 BRIX (a third drop in sugar) we add the remaining half a pack of FERMAID K

When we get down to around 5 Brix on Hydrometer which should take about 7-10 days for alchoholic fermentation. ( It should take about two weeks for Malolactic acid fermentation.) Bring Sample in for chemistry test and rent press.

Press and put into CARBOY. Let fermentation finish in CARBOY for a couple more weeks till malolactic is done and Rack.

OAK CHIPS in CARBOY.